Bienvenue chez Everest Plastik

Mouleurs d'innovation…

Chez Everest Plastik, nous faisons plus que mouler le plastique, nous moulons l'innovation, en transformant des idées en produits.

De l’étape de la sélection des produits bruts à celle de l’expédition, nous nous assurons de maintenir un contrôle de la qualité très strict

Depuis ses débuts en 1999, Everest Plastik Inc. est devenu un leader dans l’industrie du rotomoulage au Canada atlantique

Everest Plastik Inc. occupe maintenant plus de 24,000 pi. car. d’espace de production et opère quatre équipement de rotomoulage afin de mieux servir sa clientèle. L’ajout récent de plus de 8,000 pi.car. d’espace d’atelier d’usinage pour la fabrication de moule et outillage vient compléter sa gamme de services offerts.

Depuis ses débuts en 1999, Everest Plastik Inc. est devenu un leader dans l’industrie du rotomoulage au Canada atlantique. En croissance constante, Everest Plastik Inc. occupe maintenant plus de 24,000 pi. car. d’espace de production et opère quatre équipements de rotomoulage afin de mieux servir sa clientèle. L’ajout récent de plus de 8,000 pi.car. d’espace d’atelier d’usinage pour la fabrication de moule et outillage vient compléter sa gamme de services offerts. Un entrepôt de 16,000 pi. car. permet le stockage de la matière première et des produits finis.

Everest Plastik Inc. est fier de travailler de concert avec sa clientèle. Nos techniciens qualifiés et notre personnel de soutien vous assisteront dans vos besoins en rotomoulage. Peu importe la quantité, notre désir est de maintenir nos coûts compétitifs dans l’outillage et la production de la conception du produit à sa livraison.

Plus de détails

Consultez! Les idées sont contagieuses. Nous sommes toujours prêts à aider nos clients à concrétiser leurs id&eac

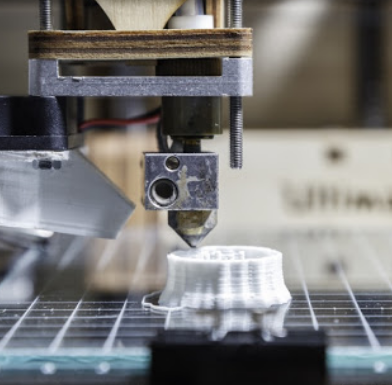

Notre équipe de design et conception travaille avec les logiciels de modelage et DAO 3D les plus récents.Notre approche multi-discipl

Les logiciels de modelage 3D nous permettent de produire des ébauches peu coûteuses et de faire des essais virtuels avant de passer &a

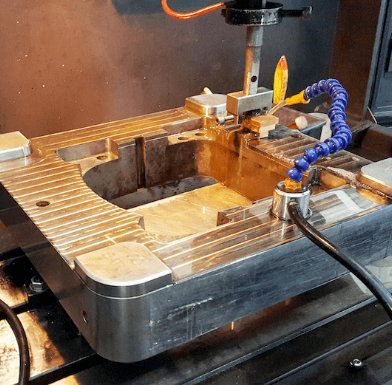

L’atelier d’usinage de Everest Plastik, chargée de la fabrication des moules, complète la gamme de services essentiels po

Everest Plastik, avec ses nombreux équipements de rotomoulage, a maintenant la capacité de fabriquer une grande variété

Afin de livrer un produit prêt pour la mise en marché, Everest Plastik propose un assemblage partiel ou complet des produits fabriqu&e

Pour toute demande, veuillez remplir notre formulaire de requête ou appeler le 1-506-395-5588 puis notre équipe vous contactera dans les 24 heures.

© 2020 EverestPlastik All Right Reserved.